News

Rust Free Testing at Refineries

Rust-Free products offer numerous benefits. They are both user-friendly and cost-effective, as well as corrosion-resistant.

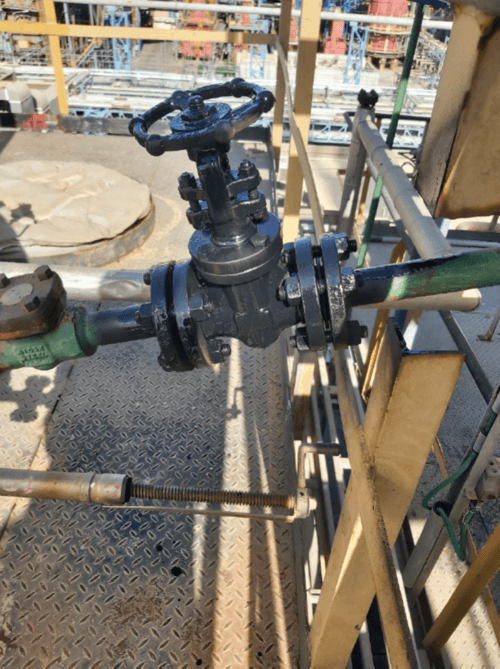

An experiment using Rust Free was planned to assess the efficacy of the product and the process of application.

This report provides the results of the initial tests from the field as well as the complete drying.

Test results from field tests:

The product was applied in the facility, warehouse, and tower-631 container F-405, and the chimney.

It was also applied on a dome-305-c 125.

The product was simple to work within the warehouse and created a solid, thin layer of protection on all objects. It covered pipes, plates, and arches.

All objects had rust levels that ranged from 0.05 or 0.1 millimeters. The things were cleaned before application.

Photos 1,2,3, and 10/21/2020 show the results of the experiment.

Excellent results from facility 136 except for one pipe that is on tower E-631. The extent of the rust hindered the proper application.

RUST & SURFACE FINISHING

Test of Rust Free usage on steel prior to painting

When it is applied to steel, it forms an emulsion of milky consistency that is cured to form a waxy solid over the course of a few hours.

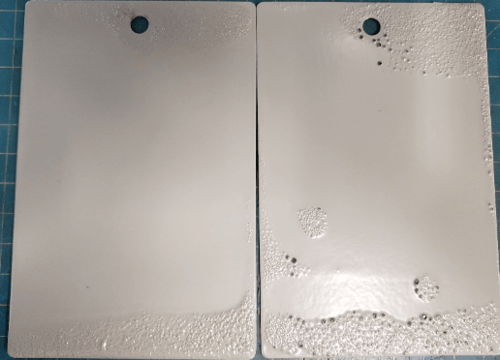

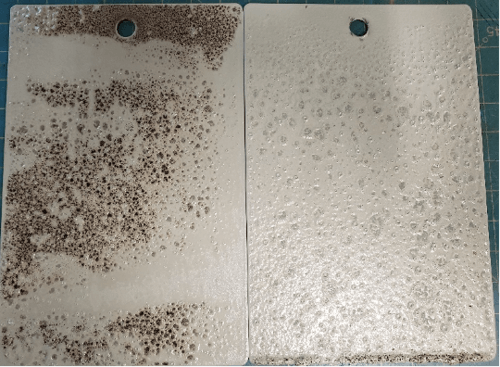

The next photographs illustrate panels that were powder coated following Rust Free. The first set of images shows panels that haven’t been cleaned; these panels are severely blistered. When the panels are washed with a hose fitted with a normal nozzle, the waxy layer is removed to a large extent. When the coating was removed, the paint was applied and looked normal, but where Rust Free remains, the paint started to crack after the curing.

The PDS for Rust Free recommends that the coating is removed by the pressure washer the following cure. A high-pressure nozzle was attached to the hose to ensure that the coat was completely cleaned. The higher pressure of rinsing enabled the removal of the coating. The surface of the steel revealed some texture/color differences compared to the uncoated steel.

Powder coat over Corrosion Cure with mild rinse

Powder coat over Corrosion Cure with no rinse

Powder coat over Corrosion Cure with rinse

Help with Rust on boat lift

A brand new pole made of new metal was placed at our dock, directly towards the ocean. All structures were cleaned using Rust Free , except for the pipes that hold the poles.

It was exposed to extreme weather, which included a hurricane, over many months. The area that was not treated was covered with a PVC pipe and a cap that stopped rainwater from getting into. This PVC pipe was taken off after a couple of months. As you can see, the lower part is extremely and rusted. Rust Free also protected the adjacent region.

The entire area covered by the plastic poles is covered with Rust particles waiting to fall off the metal. It’s Fe3o4 which is a layer of protection that is similar to corten/weathering.

This is due to the treatment by the Rust Free.

PVC Cover over the area that wasn’t treated by Rust Free

Black color metal – Full Rust

Brownish color metal – Treated by Rust Free

RUST FREE IN A SOLUTION OF SULFURIC ACID SGS Australia

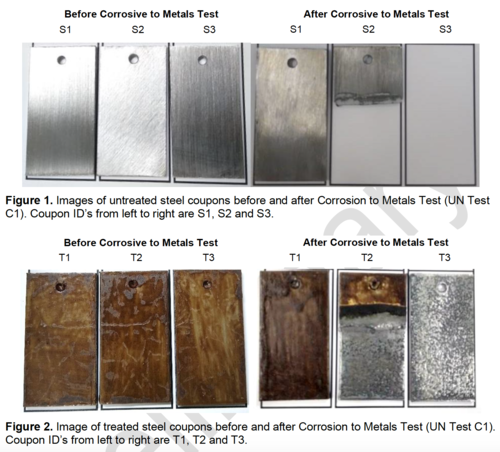

SGS Australia ran untreated metal compared to treatment with Rust Free in the presence of 33 percent sulfuric acid.

This test is relevant to both the waste and mining industries, which employ sulfuric acid or similar. It is pertinent to mention that these industries employ a more dilute acid that is more of a 5-10 percent solution.

Tests were conducted on three samples that were not treated and three treated samples:

The first two samples in both (S1 and T1) were placed over the solution, and nothing occurred with respect to the metallics.

The second samples were taken (S2 and T2) and submerged at a quarter-way point in the solution. The portion of S2 metal submerged was completely gone by the acid’s effects.

Then, they obtained the third sample (S3 and T3) and submerged them completely in the solution for seven days.

The S3 metal completely vanished due to the acid’s effect, while T3 metal completely disappeared. T3 metal lost over half of its mass.

Another test was performed on a metal that was fully submerged (another S3) into the solution, it was found that the metal disintegrated after 18 hours.

It’s hard to figure out how to estimate the resistance of different metals that incorporate our Rust Free by using various acids.

However, we can confirm that the results demonstrate that a metal treated using Rust Free produces a superior result than one not treated.